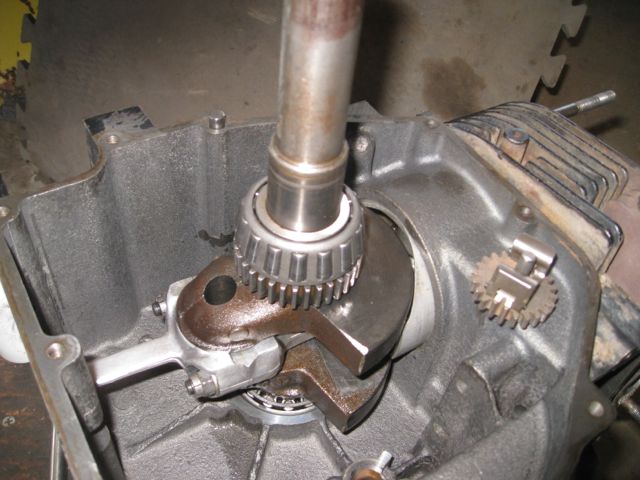

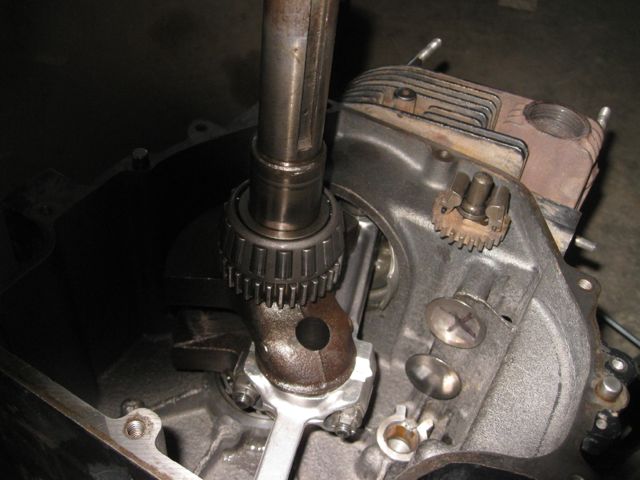

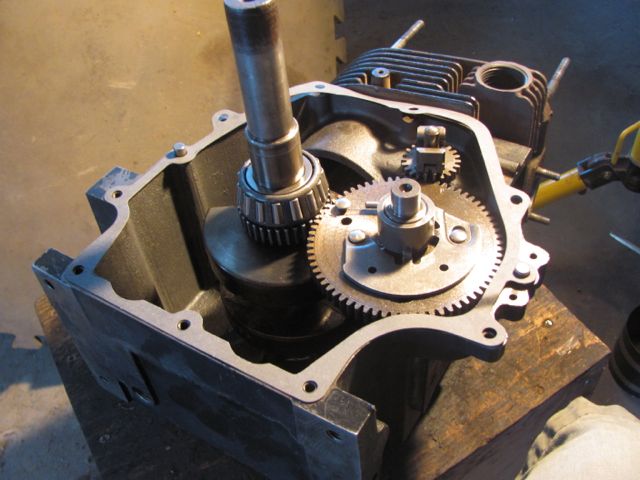

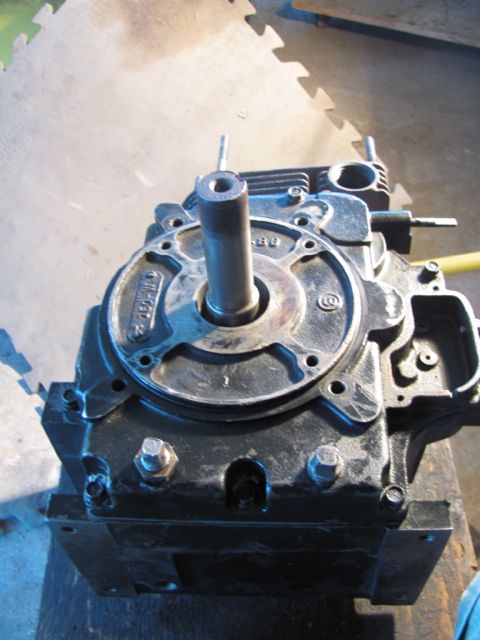

Decided that I would bite the bullet and retorque the head bolts on Wally… To be able to get at the head bolts, I have to pull off his hydraulic pump… Which means pulling the pulley off the hydraulic pump… Sigh… Did I mention that my garage has eaten at least TWO of those little dinky keys off the hydro pulley pumps in the past? Make that… THREE now! So I DID something about it! Now that I’ve used up all the spare chunks of key I had lying around holding the spare pulleys onto my spare pumps, I actually went out and BOUGHT a length of key to cut my own!

Ta DA! And, just to be thorough, I replaced the ratty, banged up key on Bror’s hydro pump too! Oh, and I retorqued the bolts on Wally’s head. Now I just have to put everything back together! The thing I learned today is that I really should start using the air impact more to pull those stubborn nuts off. I bent Wally’s hydro pulley a bit trying to use a pair of pliers to hold it still while I tried to wrench the nylock nut off the pulley… Thought, why don’t I fire up the BIG compressor and use the air impact? Took that nut off in no time flat!

-

Recent Posts

Recent Comments

- littletractorguy on Got the rototiller all mounted up on Wally

- Bill Collins on Got the rototiller all mounted up on Wally

- littletractorguy on An update on Ernie…

- Tim Boyd on An update on Ernie…

- littletractorguy on All My Deeres are finally home!

Archives

- May 2019

- May 2018

- October 2017

- May 2017

- June 2015

- April 2015

- October 2014

- July 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

Categories

Meta

Blogroll

One of the things I quickly discovered is that its almost impossible to pull the lock pin with the cable at an angle. and I know one of the tractor forum guys mentioned using pulleys… But I don’t have any of those handy. What I DO have is some 1/2″ threaded rod, some 1/2″ nuts and some plate washers. Turning the pin upside down so the grabby thing is angled downward makes it function much better. However, I can’t get the pin to pull if I have the blade raised all the way up…

One of the things I quickly discovered is that its almost impossible to pull the lock pin with the cable at an angle. and I know one of the tractor forum guys mentioned using pulleys… But I don’t have any of those handy. What I DO have is some 1/2″ threaded rod, some 1/2″ nuts and some plate washers. Turning the pin upside down so the grabby thing is angled downward makes it function much better. However, I can’t get the pin to pull if I have the blade raised all the way up…

And no project would be complete without a video!

And no project would be complete without a video!

Guess I can’t expect a 57 year old spring to last forever!

Guess I can’t expect a 57 year old spring to last forever!

Thank you so much, anonymous friend, for saving my butt!

Thank you so much, anonymous friend, for saving my butt!  Whoo hoo!! Woot, woot! I couldn’t be happier!

Whoo hoo!! Woot, woot! I couldn’t be happier!