So, I hauled out the piston, slinger, camshaft, crank and tappets for some pics in better light this morning…

Here’s everything laid out…

The camshaft

Frankly, I think the camshaft looks pretty good… Tops of the lobes are a bit scuffed, but not too bad… Not sure where to measure to and from…

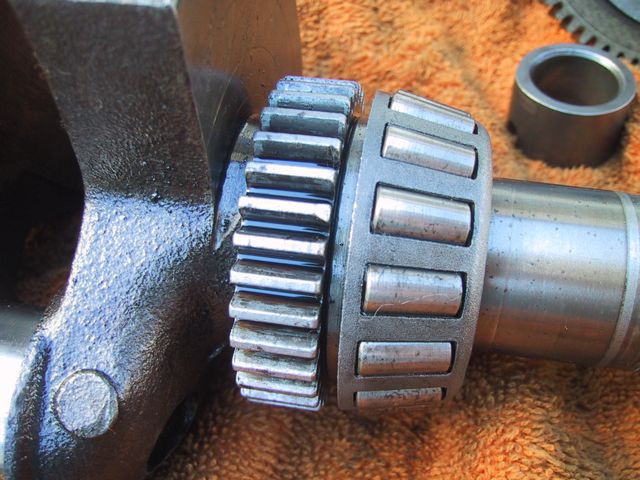

More details of the crankshaft

So, the crank pin actually measures within tolerances (I did find a set of digital calipers at Peavy Mart last weekend).

Bearings both look clean and spin well

THIS is the only spot I’m worried about on the crankshaft, the end of the pulley side of the crank… Dunno if I should be trying to clean it off or what…

Here’s my nicely marked tappets

I think the piston bearing areas look pretty good, and the slinger is fine

There was some grunge in this spot, most of it came off with a light scraping

Obviously, I’m gonna have to get this cleaner, or get it machined…

So, here’s my thoughts… In my limited experience, I think everything south of the cylinder inside this engine looks really good… I think the cylinder needs a honing/polishing, everything north of the cylinder on the intake side needs work… AND the piston face and rings need work… My theory is that the engine got shut off with the intake valve open, allowing moisture into the cylinder… Fortunately, the rings DID keep it out of the bottom half of the engine… Just the intake valve and tappet suffered, and a bit got past the rings… This must have been what locked up the engine to begin with… Rings stuck against the cylinder wall about 2/3rds of the way up (there was a bit of a mark there when I cracked the head….)…

LTGal has suggested taking the block in to one of the local Deere dealers here to see if they will check it out and hone it for me, and possibly clean out the valve passages and valve guides…