Quote:

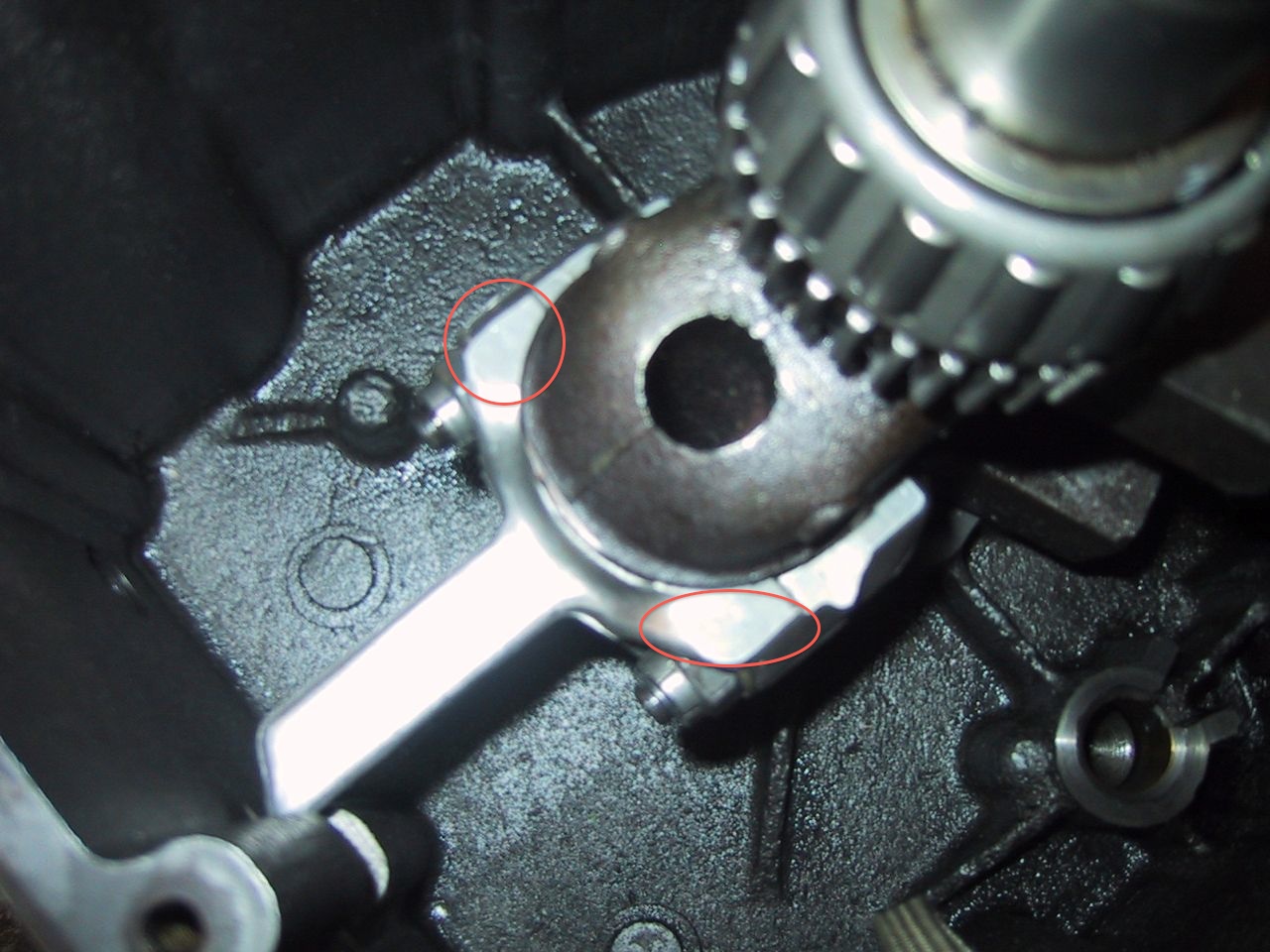

Okay, so I TAP it HERE! And assembly lube can be any medium-weight oil, right? So the OTHER good news last night was, the governor arm that I felt was a bit loose, I can get another out of Donor Frank…. I ALSO took some time last night to pull the valves, valve springs and keepers out of Frank. The springs at least look a lot better than the ones currently for Bror… The valves weren’t as crusty, and the intake cleaned up really nice, but I might as well stay with the valves I’ve got. Except for the head, which is crusty from an electrical fire, Frank seems to be in pretty good shape… Oh, and I ordered the light for the sandblasting cabinet the other night… |

-

Recent Posts

Recent Comments

- littletractorguy on Got the rototiller all mounted up on Wally

- Bill Collins on Got the rototiller all mounted up on Wally

- littletractorguy on An update on Ernie…

- Tim Boyd on An update on Ernie…

- littletractorguy on All My Deeres are finally home!

Archives

- May 2019

- May 2018

- October 2017

- May 2017

- June 2015

- April 2015

- October 2014

- July 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

Categories

Meta

Blogroll

After squirting some assembly lube up into the bore from the crank side, rotate that crank so you can get to the rod cap readily.

After squirting some assembly lube up into the bore from the crank side, rotate that crank so you can get to the rod cap readily.