This morning I took the time to get down to brass tacks on creating the door hardware.

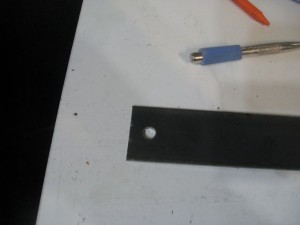

Here’s the first hole I cut in the 1/8″ x 1.5″ steel that’s going to form the hangars

Mounted the sheave, just to see how it would fit

Then tried to figure out how to do the bending. Tried putting it into my vice and bending the 4′ piece of steel around, that didn’t work because a) I don’t have enough clearance in my workroom to bend around like that and b) I don’t have my vice permanently mounted. A flash of inspiration led to THIS:

I ran a 2.5″ x 3/8″ bolt through the side of my workbench, threw the steel stock onto it, the sheave onto it, and secured it all with a nylock nut. Securing it that way enabled me to do THIS:

Not totally perfect, but I’m getting the hang of it. The plan is, I need to bend BOTH ends of the 4′ bar, THEN cut it in half, then bend the OTHER end of each half and drill the holes, THEN cut each of THOSE guys in half so I wind up with 4 hangars shaped like this one… Then I drill 2 holes in the other end of each hangar for mounting them on the doors…

The BIG problem is drilling the holes. I quickly found that the drill would drift a LOT, so my first one the holes don’t quite line up. What to do, what to do? I know! Go shopping!

Ta-DA! THIS is going to make all the rest of the holes a breeze, I hope! Now I just need to figure out what speed to set it to for drilling mild steel… Didn’t have a chance to try it out today as I had a few other commitments, so stay tuned!

(PS, LTGal’s okay with this purchase, as it can be used/useful for HER projects too!)