|

So, answered an ad on Kijiji on the weekend, a guy outta town had a hydro pump, ram and lift hardware from a 1968 112h. Cross-referencing the pump on the parts catalog told me it was the same one as in Bror (67 112h, although it didn’t look like the ram was.

Decided last night that I’d make a road trip out there, and I’m glad I did…. The tractor had been left at his acreage by the PO, there’d been an electrical fire, so it was not drivable… Since the PTO clutch had seized and cracked, he had decided to repower it with a different engine… So he still had all the engine bits that he didn’t need. Decided last night that I’d make a road trip out there, and I’m glad I did…. The tractor had been left at his acreage by the PO, there’d been an electrical fire, so it was not drivable… Since the PTO clutch had seized and cracked, he had decided to repower it with a different engine… So he still had all the engine bits that he didn’t need.

Turns out yes, the ram is different, but the hydro pump is the same,

and even better, the ’68 SF shared the 10HP Tec engine with the ’67 (with a few differences… Electronic ignition instead of points, alternator instead of generator… ). So I took the engine and the carb as well…

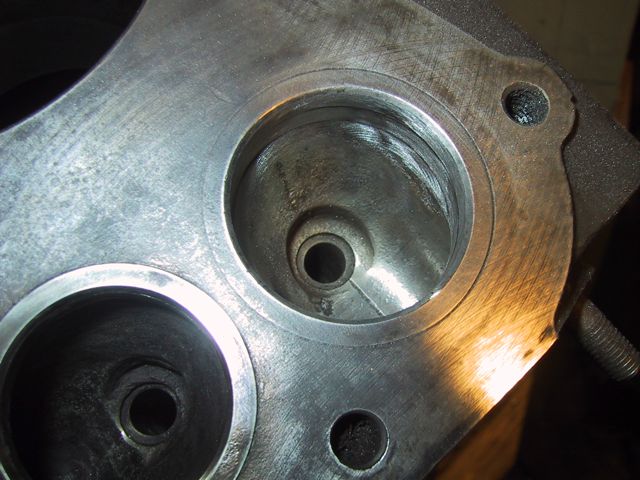

The carb is a bit of a writeoff (loose throttle shaft) but its nice to have one I can dork around with to learn about, rather than messing with the “super-carb”. Engine still spins and still has compression, and after doing some crossreferencing with the parts catalog it looks like it will give me pretty much an entire set of bits that are otherwise unavailable or very spendy (piston, connecting rod, slinger, wrist pin, valve springs, valves, tappets, camshaft, crankshaft, crankcase breather) to have as spares…. I LIKE spares…. |

-

Recent Posts

Recent Comments

- littletractorguy on Got the rototiller all mounted up on Wally

- Bill Collins on Got the rototiller all mounted up on Wally

- littletractorguy on An update on Ernie…

- Tim Boyd on An update on Ernie…

- littletractorguy on All My Deeres are finally home!

Archives

- May 2019

- May 2018

- October 2017

- May 2017

- June 2015

- April 2015

- October 2014

- July 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

Categories

Meta

Blogroll

I would use more ( quicker) up/ down movement as you spin the hone, whoosh whoosh whoosh, not w h o o s h, w h o o s h …

I would use more ( quicker) up/ down movement as you spin the hone, whoosh whoosh whoosh, not w h o o s h, w h o o s h …