Well, been a little busy, so I haven’t been keeping people as up-to-date as I should about where I am with Wally…. So here’s a LONG one for you… Over the past, oh, couple weeks, I’ve snuck out for an hour here and a couple hours there, then finally got a good chunk of time Friday, Saturday and this afternoon.

So on FRIDAY I decided I’d take the plunge and run Wally’s block to a local engine shop to get them to mic it (since all my eBay attempts to buy inside micrometers have been abysmal failures)… They said he was in spec! Yay! They also said I should REALLY do new rings if I’ve got it this far apart… and they figured the NAPA down the street would carry them… So I stopped off there, and dropped 53 bux to order a new set of rings… Should be here by Wednesday…. Sooooo, if I’m going to do new rings, I should hone TOO… Off came the bearing plate, AGAIN, and out came the crank (didn’t really want to hit the crank with the hone accidentally…)

Then I broke out my 3-stone hone…. Here’s pre-hone:

Here’s post-hone:

Can’t see TOO much difference between them in the picture, but I got some crosshatching going…

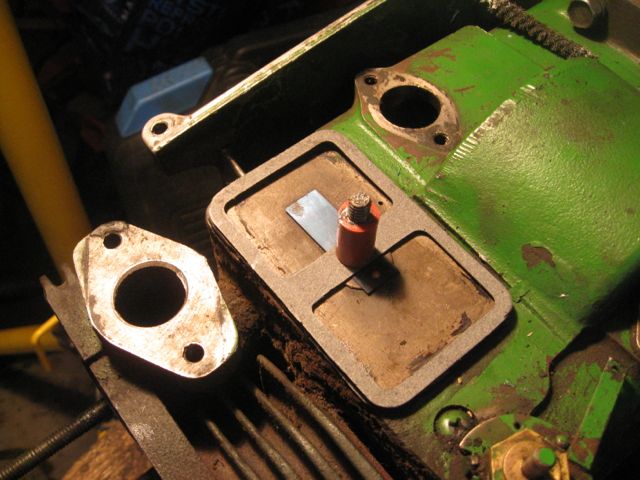

Also figured out how the breather comes apart… (well, actually I dropped it and it fell apart… needs a good cleaning!)

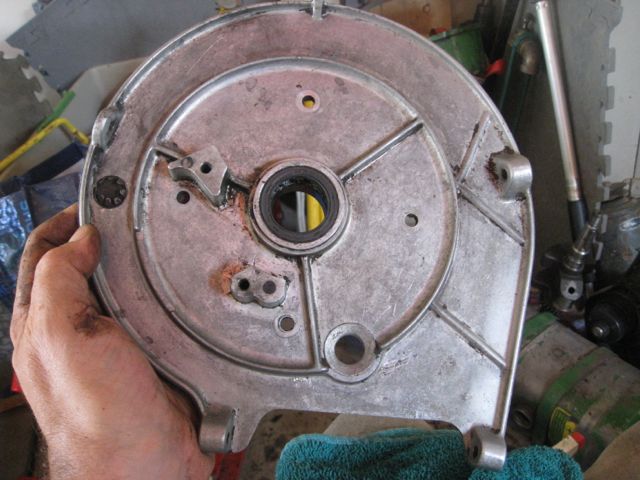

And cleaned up the bearing plate a bit more:

So that was last Friday…

Saturday, I went out and dropped the crank back in… Check it out!

(this is me figuring out how to better use the digital macro on my Canon tractor-cam!). Got the timing marks all lined up, all ready to drop the bearing plate back on… again…

But remember, a few posts back, I was wondering about torque charts and bolts and things? Well I figured I’d learned how to read the the torque chart, so I broke out the torque wrench and went to torque up the bearing plate bolts… 7/16 bolt… Chart says 35 foot/pounds… Um… okay….

Turn, turn, CRINK!

UH-OH

WTH?!?! Chart says 7/16 bolt, 35 foot/lbs… Seems like a LOT… Oh wait… That’s for a 7/16 BOLT, with a 5/8 HEAD… These are 1/4 bolts with 7/16 heads… Oh… 6 foot/pounds….

Fortunately, it snapped close to the head, and I was able to pull the bearing plate off (again) and…

(I know, I know, I’m wearing my ring! Before I start on the electrical, I’ll go drop it into the safety deposit box at my bank).

So, what to do? Well, a quick trip to the local Co-op hardware for $0.70 worth of bolts, and HERE’S my bearing plate, on AGAIN!

(these are a higher grade of bolt, hope that doesn’t cause me a problem)

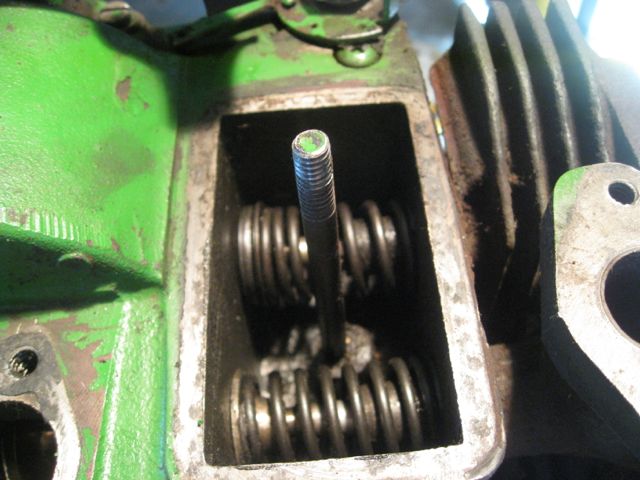

Just had long enough left on Saturday to drop the valve springs and retainers in… Notice the shorter exhaust spring with the rotator on it! Unique to the 110H! Cool huh?

Fast forward to this afternoon now, which I took off due to having to work last night til about 1 am…

So, time to drop the valve keepers on… These guys are a bit different than the ones for the Tec outta the 112… They’re 2-piece collar-kinda-dealies

The BOOK says use the handy dandy keeper tool, which in the pic looks like a funky set of pliers… However, I suspect I woulda had to BUY that 40 years ago.. The other suggestion for putting the keepers on is to grease them up and hope they stick…. Sooo….

(that’s a keeper on the end of my flat screwdriver, all gobbed up in lithium grease)

Wasn’t sure how this was gonna work, but I broke out the valve-spring compressor and went to! Aaaaaand….

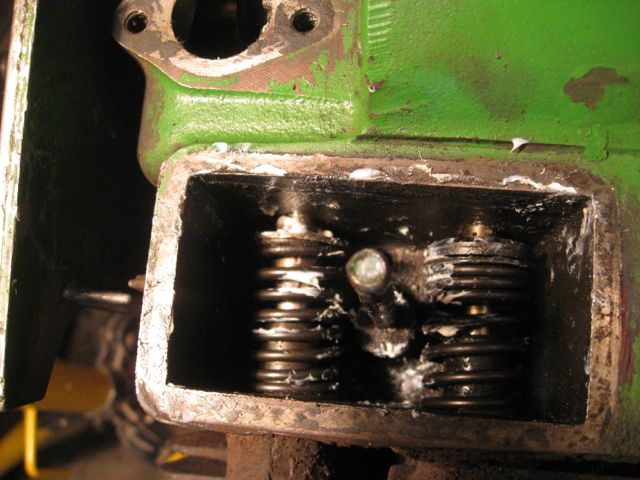

Success!!!! Really on a roll now! Another 20 greasy, gobby minutes, and voila!

On to the rest of the finagle-y bits! Like the breather! Changed out the old cruddy fibre filter stuff for this,

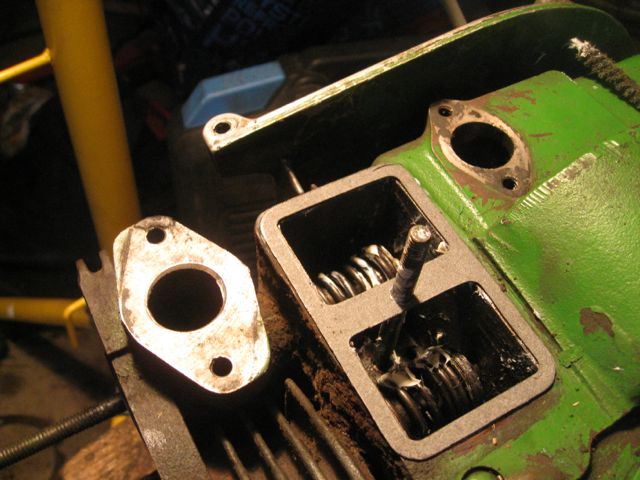

then tried to put the breather all together and drop it over the post… Well, THAT didn’t work too well, but what if I do it in layers?

Gasket…

Plate with reed valve, another gasket, the seal for the post (note the breather hole in the down position! Dang I’m good!).

And finally the cover!

Next, this is the timing hole cover isn’t it? This was the only gasket I could find that fit this piece….

On to the points! I know I should replace them, but I figure I’ll buff them up a bit and see how I do… So, before…

and after a brief buffing with some fine grit sandpaper…

Got them all strapped back into place and dropped a bit of light oil on the pushrod… Here’s the very important rubber insulator, AND another new gasket!

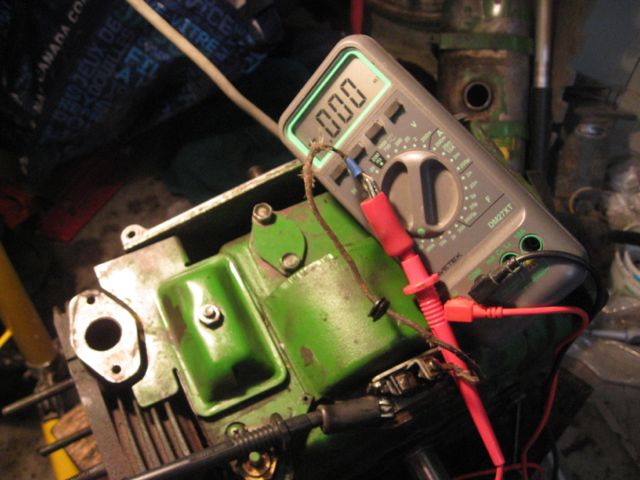

Also figured I should test to make sure that my points wire is good… So out comes the meter, one lead on ground, other on the wire, 0.00 ohms! Looks like we’re good to go!

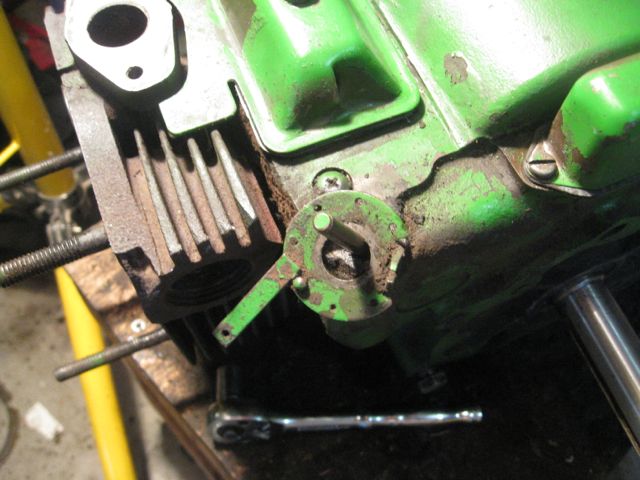

THEN I made a bit of a mistake… I figured I’d clean up around the governor and the regulating disk, so I undid the bushing that held it in place…

And of course, the cross shaft fell out of place! DOH! I figured I’d have to pull the bearing plate AGAIN and futz around fixing that… Well, lets pull the oil pan off (I’d put it back on while I was doing the valves so the engine would sit more level) and see what we can do looking down into the camshaft/governor area… And see if I can play with my digital macro again!

So, THIS is looking up the BOTTOM of the engine (which is upside down on my stand, into the cavity where the governor sits. On the right is the arm of the rockshaft that gets pushed outward to the right by the governor cap (on the left) as it speeds up and gets pushed up by the force of therotating weights (this whole governor thing, I just find fascinating!)

So, once I was sure it was in the right spot, I secured it with the bushing

popped the regulating disk back on,

and put the speed control on and secured the governor arm according to the instructions!

And so, getting closer!

Just need a set of rings, and I can drop the piston and connecting rod back in!