So, I got out to my dad’s warehouse today where Cranky has been in storage since, oh, last November, I think… Blew up his tires, went to roll him out – URK! No roll-y! DANG IT! Brake was off, shifter in neutral, but no spinning of the wheels! Fortunately, my dad is handy with his forklift, and got Cranky all loaded up…

After a bite to eat, I went to head back home… Before I left, I figured I’d take a peek under Cranky and see if I could see anything wrong… Well, the brake/clutch pedal was pretty loose all the way down to the last few inches of pedal, and the variator lever just barely does anything…. So something was jammed… Worked the brake pedal a bit, then decided to just head’er out and hope I could drag him off the trailer…

Got Cranky home, backed the trailer up to the back gate, let the end gate down on the trailer, undid the straps, got ready to have NO fun dragging a 600 pound tractor off my trailer and…

he just rolled right off as easy as you please! A little bit of pushing and some steering and some rearranging, and now here’s my two buddies, out under the sunshade!

Of course, now……

I can put my evil plan into ACTION!

buh-BUH–BUH!!!!!

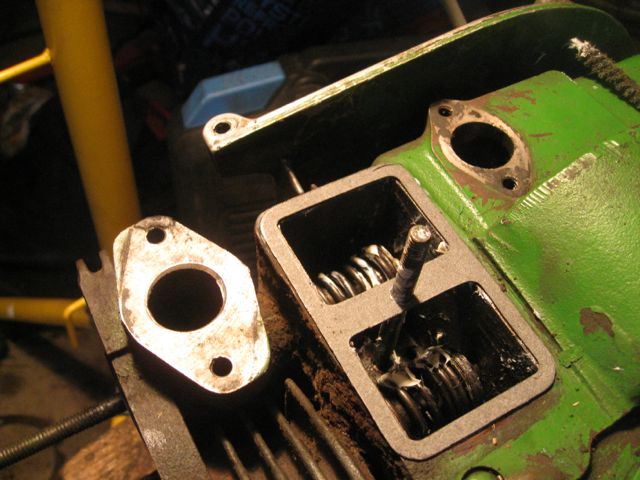

And so, I popped the hood on Cranky and the first thing I found was…. What the heck?

Cranky’s got a Walbro LME carb from a 112 on him! And I noticed, a NOT connected choke linkage… AND, I also noticed,

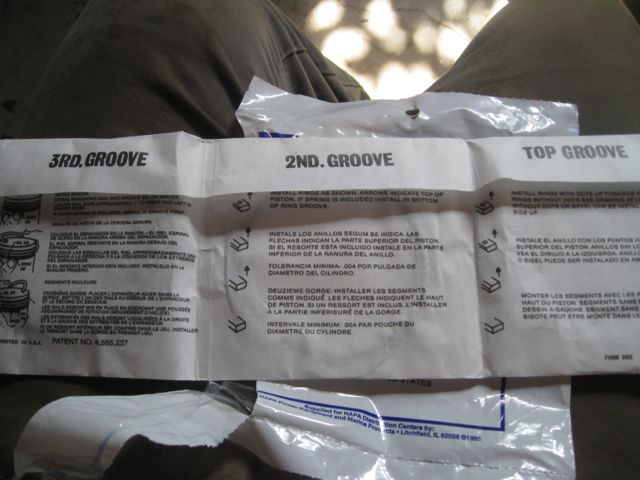

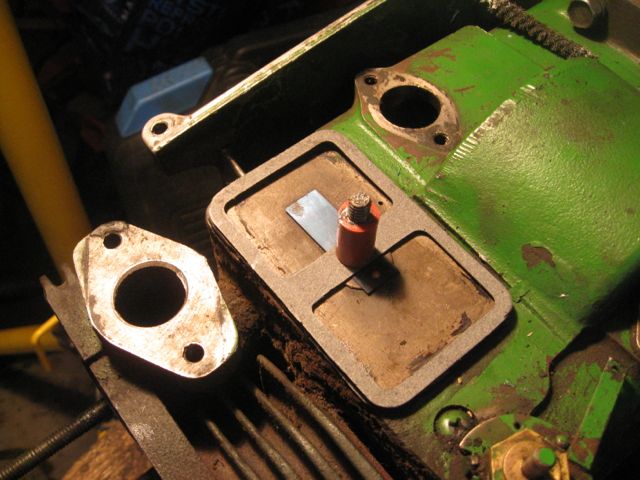

the air cleaner assembly from a 112 as well! Whoa! I haven’t even STARTED and already we’ve got shades of Frankenstein! So, I pulled the tins off, and went after the head… It came off really nicely, BUT….

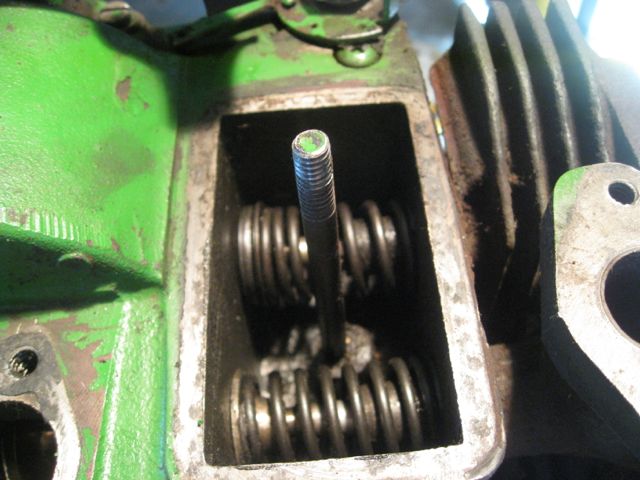

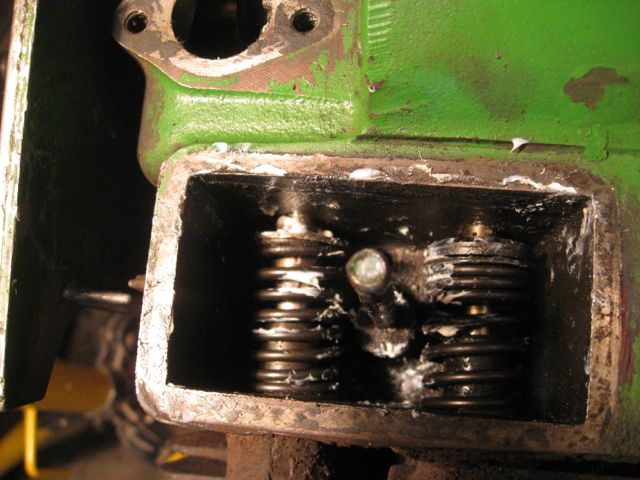

and

Back as midnight, all along the cylinder walls and on the head, AND (not surprisingly) no connecting rod…

Well, might as well pull THIS engine out too, since I need some bits from it!

Its got a nice new starter-generator belt,

and I was able to pull off the generator mount for use on Wally, as well as the piece of frame that Wally’s PO had butchered when they did their home-repair on his generator mount…

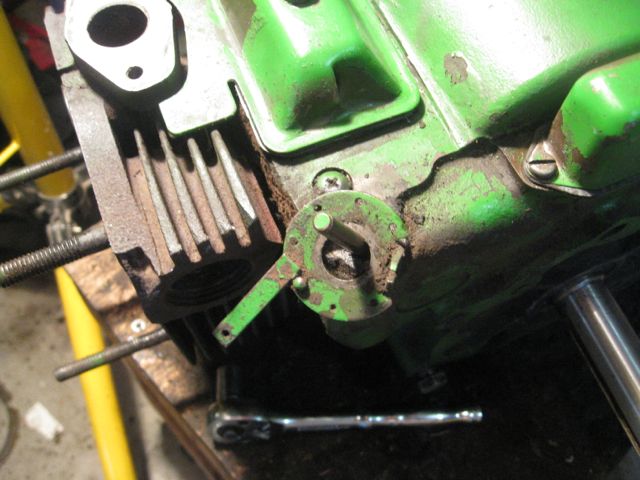

Figured I’d try to remove Cranky’s flywheel before pulling the engine, just because… And I discovered a neat trick… I had a heck of a time with Wally’s engine, holding the flywheel still while I pounded on the nut… So… took my big 1 1/16 wrench and wedged it like so…

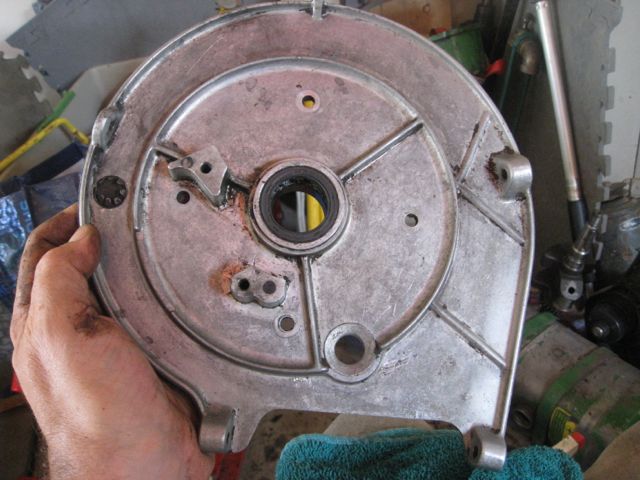

Worked like a darn! Without even breaking any flywheel fins! Which is another good point, I can use this flywheel on Wally’s engine, since his has a broken fin! Broke out the puller, and…. BAM!

Then I crawled underneath Cranky to try to drain the oil, and I was in for another pleasant surprise! Guess what I found?!?!

I had NO IDEA the helper spring on the round fenders was THIS BIG! Its HUGE! Now, I don’t know if its really required on the hydraulic lift, but it would be a nice addition to Ernie, then…

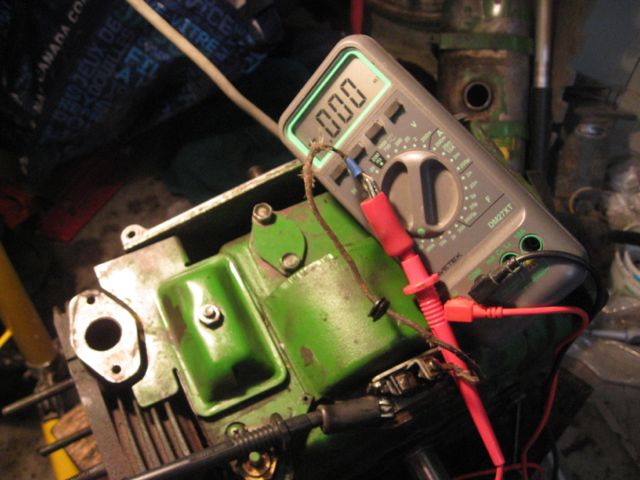

I also noticed that somebody must have redone all the electrical on Cranky as well, because the wiring harness looks nearly new… AND he has his neutral start switch intact! He’s just a gold mine for parts! Rims are good, looks like I can scavenge some 3/8″ clevis’s for another project I might have starting soon…

Just too bad about the rod. I’ll have to rip into the underside of his engine and see what I find… I just don’t get it… Somebody put in the effort to get Cranky a helper spring, put a new generator belt on and redo all the wiring, but then they strapped the WRONG carb on, and ran it at half-choke all the time? Wouldn’t THAT be what caused the thick black soot all over the cylinder and head? Running it rich all the time like that? Which would then have caused overheating, I’d guess, having that much carbon buildup… The post-mortem on his engine should be interesting…

)

)