|

Okay, so I just don’t really understand…. Off I went to a local major auto franchise place that shall remain nameless (to protect the innocent) to pick up some ant-seizing compound… Now granted, I’ve NEVER bought it before so I wasn’t too sure where it would be, or what it would look like… So, I go in and stop at the parts counter and say….

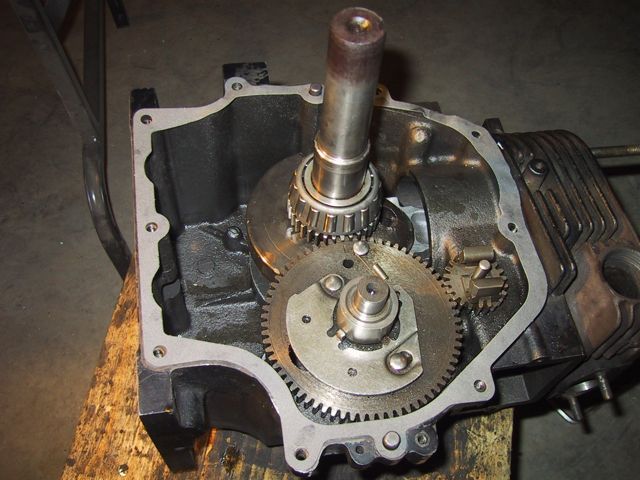

“I’m looking for some anti-seizing compound, like Never-Seize…” “Oh,” says the kid behind the counter (they’re ALL kids, compared to me), “Like WD-40”. “No, something to apply to, say, shafts, BEFORE you put, like, a flywheel on, so that it doesn’t seize onto the shaft”. “Oh…… Um, well, I don’t know if we HAVE anything like that, but all our GREASES are over there, and all our LUBES are up over there.” Oh. So I look through the grease section and don’t find anything. So I go over to the lubrication section and hunt around in THERE for 15 minutes, reading labels and checking cans and so on…. While I’m standing there looking flummoxed, a friend of mine I haven’t seen for 6 months happens by… “Hey, whatcha up to?” he says… So I tell him my sob story about not being able to find any Anti-Seize…. “Of course they have it! I just bought some the other week… Its right over here!” And there, tucked into a teeny tiny corner of the back edge of the grease shelf is this:

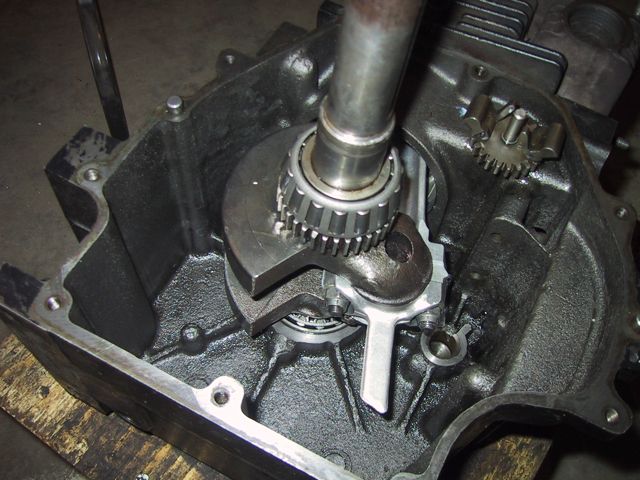

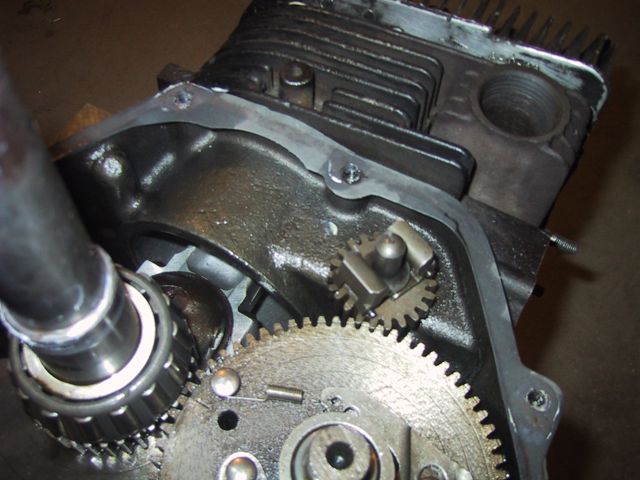

So, I make sure to go back to the parts counter, where the kid is still standing, and I say (nicely)… “Just so you know, THIS is anti-seize…” “Ooooohhh, ANTI-SEIZE! For like, copper-plating your shafts! Right!” Good thing I didn’t have my big brass-handled cane there…. Some days, I JUST don’t understand…. Okay, back to installing a flywheel! |

-

Recent Posts

Recent Comments

- littletractorguy on Got the rototiller all mounted up on Wally

- Bill Collins on Got the rototiller all mounted up on Wally

- littletractorguy on An update on Ernie…

- Tim Boyd on An update on Ernie…

- littletractorguy on All My Deeres are finally home!

Archives

- May 2019

- May 2018

- October 2017

- May 2017

- June 2015

- April 2015

- October 2014

- July 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

Categories

Meta

Blogroll

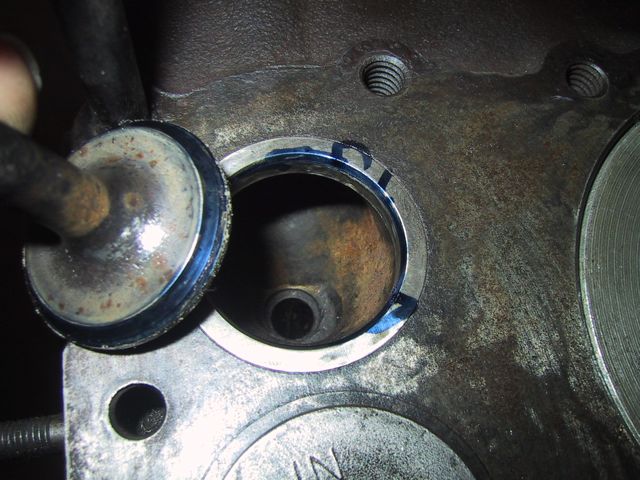

I know, I don’t have any reason for it, now that the valve stem is being ground at the engine shop…. Well, except for helping kidlet #1 make her halloween costume (you don’t want to know… at least until I have pictures)… AND it was on sale…. and I’ve always wanted one!

I know, I don’t have any reason for it, now that the valve stem is being ground at the engine shop…. Well, except for helping kidlet #1 make her halloween costume (you don’t want to know… at least until I have pictures)… AND it was on sale…. and I’ve always wanted one!

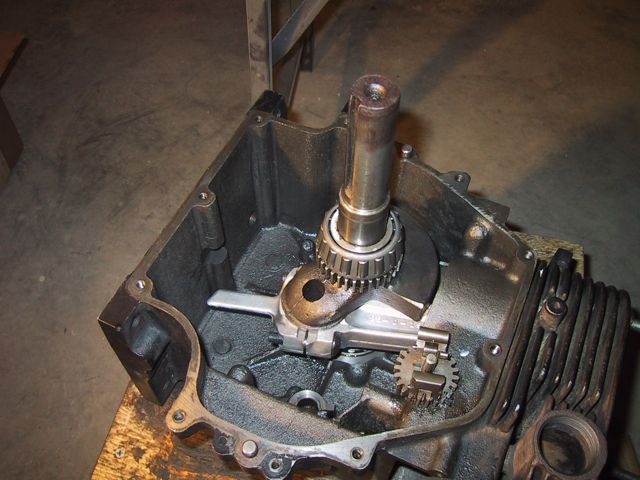

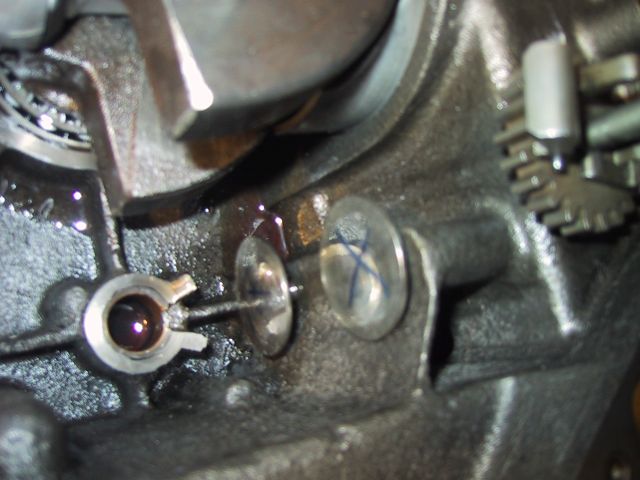

After squirting some assembly lube up into the bore from the crank side, rotate that crank so you can get to the rod cap readily.

After squirting some assembly lube up into the bore from the crank side, rotate that crank so you can get to the rod cap readily.